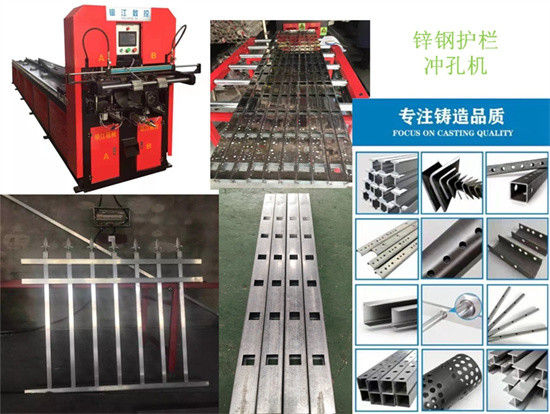

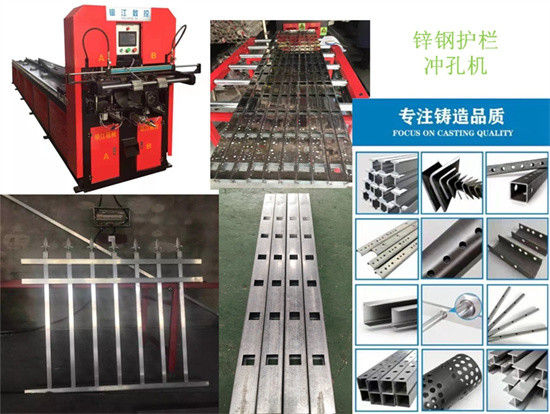

Automatic guardrail square tube punching and shearing machine

Yinjiang Machinery Equipment Co., Ltd. was established in 2014.It

is an enterprise specializing in the customized production of

various stamping machines.The equipment can be customized to

process angle steel, C-shaped steel, flat steel, square pipe, round

pipe, H-shaped steel, I-beam, channel steel, aluminum alloy

profiles and other workpieces.It is widely used in solar energy,

construction machinery, electric power towers, environmental

protection, automobiles, furniture, supermarket equipment,

shipbuilding, building materials processing and other industries.It

has served more than 200 listed companies, including state-owned

enterprises, and more than 9,000 small and medium-sized enterprises

in China.And the equipment is exported to Belarus, South Korea,

Canada, the United States, Mexico, Vietnam, India, the United Arab

Emirates, Jordan, Egypt, Turkey and other countries.Everyone is

welcome to consult and understand

Yinjiang Machinery square pipe punching and shearing machine is

widely used in furniture hardware pipes, safety fences, fences,

solar brackets, construction equipment, commercial supermarket

equipment and other industries punching and shearing processing

[Operating system]

1. The working pressure is adjusted continuously. The oil pressure

circuit adopts a zero-load design, and the oil pump motor is

designed with a low-level digital frequency to effectively reduce

noise and sound, thereby increasing motor performance and life.

2. When the cylinder drops and actuates, it adopts a fast-to-slow

oil pressure differential circuit design. The characteristics of

high-speed descent, low-speed processing, and high-speed recovery

enhance the stability of the workpiece forming during punching. In

addition to increasing the actuation speed, it can effectively

reduce the horsepower load to facilitate power savings.

3. The electronic control system is equipped with a man-machine

interface, and the cylinder stroke is 150mm (the stroke can be

set). The distance adjustment adopts the design of a position

ruler, the spacing, the slow position, and the lower limit position

to make its operation accurate and simple and clear.

4. The servo motor is used to actuate, the receiving and feeding

speed can be set and quickly adjusted, and the accuracy is high,

which can increase the output.

5. The clamping force is sufficient, and the material is pushed by

the servo motor, the working positioning does not fall off, and the

stability is high.

[Operating system]

The new type of Yinjiang machinery photovoltaic bracket automatic

punching equipment has a CNC touch control surface. The same

machine has two processing production lines. One worker can operate

the production and processing at the same time, and the two lines

can punch holes at the same time (the same hole, different holes,

different size holes, holes with different hole spacing, different

processing pipe punching) Fool-like operation, servo motor accurate

hole pitch positioning, it only takes one minute to complete the

punching of metal pipes, without tolerances, ignoring the manual

operation fatigue caused by labor intensity and the delay in

work.At the same time, the processing noise and production energy

consumption of equipment production are reduced.

Equipment processing and production process flow:

Feeding-stepping up positioning-starting/automatic-punching and

forming-discharging

At the same time, the LCD smart touch display can store dozens of

different processing parameters and data.

It is convenient for repeated punching twice, no need to

re-enter/just exchange the stored data, and it can be started.

Yinjiang Machinery photovoltaic bracket punching function processes

a variety of different profiles to achieve multi-directional

punching. He can achieve solutions to various problems you need

according to your requirements, meet the needs of different

customers, and can customize projects for customers, provide

technical guidance, and tailor suitable products for

customers.First-class quality, outstanding performance, excellent

service, reasonable price" is our commitment to our customers, and

meeting their needs is our eternal pursuit.